Compressed air, as a critical power and process medium in industrial production, requires accurate flow measurement to ensure system energy efficiency and production stability. The client seeks a flow measurement solution that provides high accuracy, wide rangeability, low maintenance costs, and supports real-time remote monitoring for automated control under varying operating conditions.

Application :

Monitoring Compressed Air Flow in an Industrial Production System

Exigences :

- Wide range measurement from low to high flow

- High accuracy and cost-effective

Solution :

MT221B Insertion-type Thermal Mass Flow Meter

Application

- The client measures compressed air flow in a DN50 pipeline with the following parameters:

- Flow range: 10 – 100 Nm³/h

- Medium temperature: approximately 40℃

- Operating pressure: 0.8 MPa

- Requirement: Real-time remote monitoring of flow data to enable automated process control

Défis

- Wide rangeability: Compressed air flow varies significantly from low startup flow to high load, requiring a flow meter with a wide turndown ratio to accommodate multiple operating conditions.

- Limited budget: The client is cost-sensitive and seeks a solution that balances accuracy, stability, and cost-effectiveness.

- Easy maintenance: The system operates in a harsh environment prone to dust and wear, demanding durable and easy-to-maintain instruments.

- Digital communication needs: The flow meter must support digital communication protocols such as Modbus RTU for seamless integration with supervisory control and data acquisition (SCADA) or PLC systems to enable remote data acquisition.

Solution Provided by Metlan — MT221B Thermal Mass Flow Meter

Key Specifications:

- Measurement range: 0 – 120 Nm/s, with turndown ratio up to 1:2500

- Accuracy: ±1.5%

- Applicable pipe size: DN20 ~ 250

- Insertion length: 250 mm

- Medium temperature range: -40℃ ~ 150℃

- Maximum allowable pressure: 1.6 MPa

- Output signals: Modbus RTU, 4-20mA, pulse output

- Process connection: G1/2″ (ISO 228-1)

- Display: 1.5-inch IPS LCD capacitive touchscreen for easy local operation

- Protection rating: IP65, suitable for harsh industrial environments

- Power supply: 24 VDC

- Accessories: Includes ball valve and power module for easy installation and maintenance

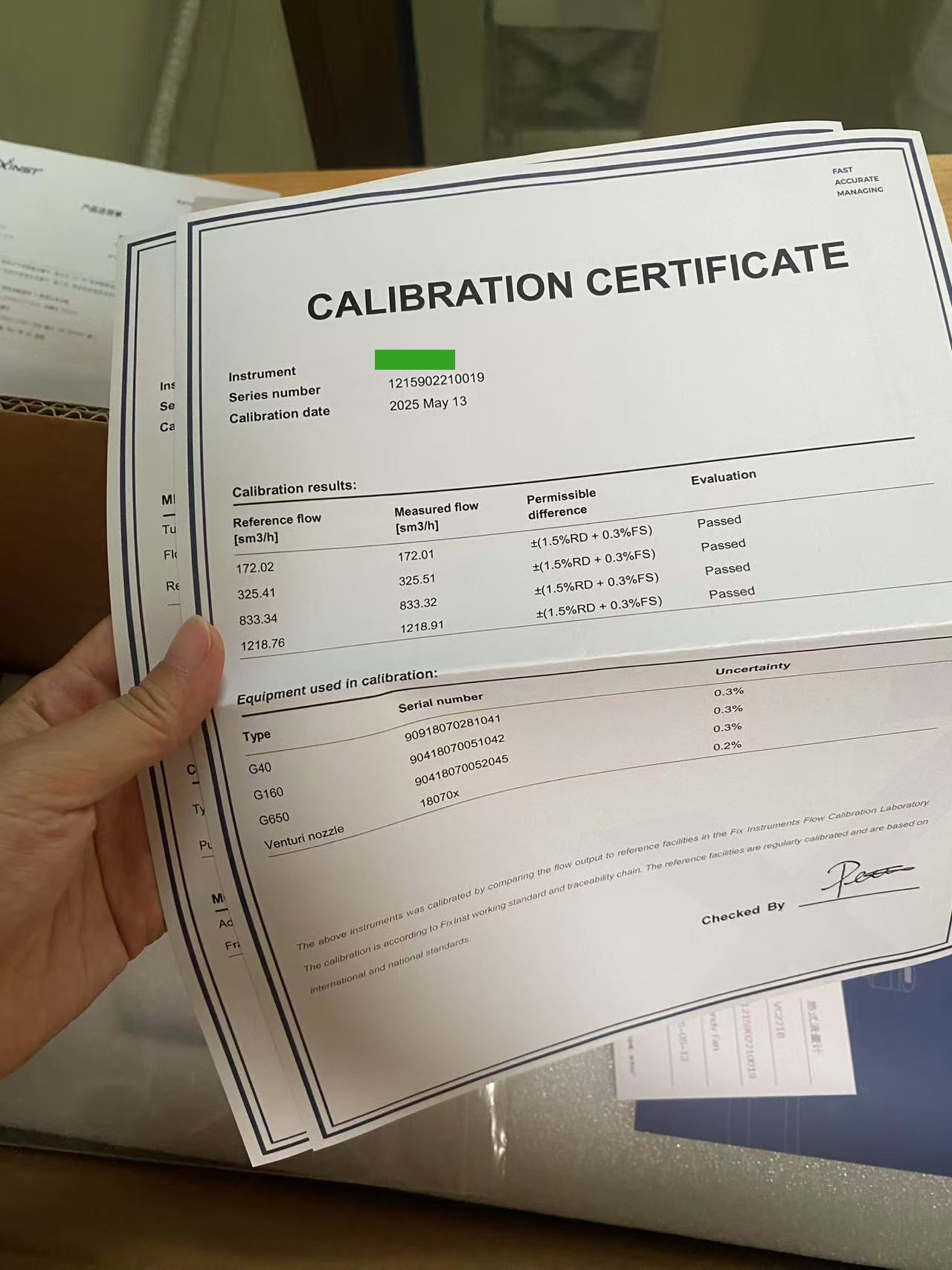

Delivery photo

Avantages :

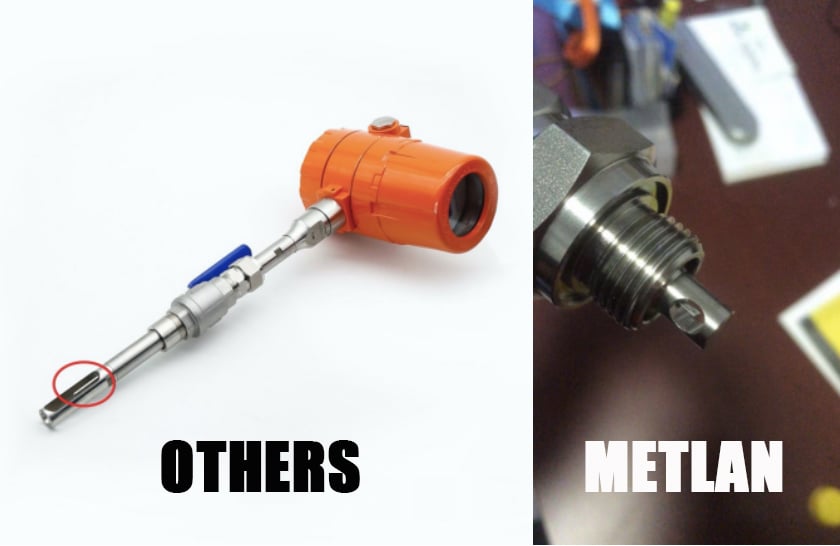

- High-precision sensor chip design

Uses advanced chip-based sensors avoiding traditional two-probe sensors with thermal adhesive degradation issues, achieving accuracy up to ±1%.

Every flow meter is calibrated prior to shipment to guarantee accuracy and stability. The model number is concealed due to this being a customer-specific OEM order.

- Rapport de réduction important

Turndown ratio up to 1:2500, covering a broad range of compressed air flow conditions from low to high velocity. - Insertion design

Supports online installation and removal; ball valve accessory facilitates maintenance without shutdown. - Digital communication interface

Supports Modbus RTU and other industrial protocols for seamless integration with DCS/PLC systems, enabling real-time remote monitoring and data acquisition. - Touchscreen display

Allows intuitive onsite viewing of flow data and parameters, simplifying operation. - OEM support

Flexible customization options to meet specific client requirements.

Conclusion

The MT221 thermal mass flow meter, with its wide turndown ratio, high accuracy, stability, and easy maintenance, proves to be an ideal solution for compressed air flow measurement. Its insertion design and comprehensive digital outputs simplify system integration and maintenance. This case demonstrates the advantages of thermal mass flow meters in complex industrial environments, helping the client achieve energy savings and enhanced automated control, resulting in significant economic and management benefits.